Compactors should be used only when dealing with general waste that has no meaningful recyclable content and to reduce the volume of waste so fewer expensive garbage pick-ups are necessary.

When waste needs to be destroyed and/or greatly reduced in volume, consider the C&M designed, highest quality PreCrushCompactor with many optional features for those demanding applications. Most “compactors” reduce waste from 1:2 and 1:4 ratios and a C&M

PreCrushCompactor will likely double those for 1:4 to 1:8 ratios.

C&M’s PreCrushCompactor has many unique features not found on other PreCrushers to solve problems that plague other PreCrushers. Some examples are the Crusher Door track and platen/ram plates are ALL replaceable wear materials designed for lubrication and wear NOT STEEL-ON-STEEL! The C&M PreCrushCompactor has two ram wipers to help eliminate waste from entering the rear of the machine and two see-through lockable cleanout chutes to make cleanliness practical.

The C&M Crusher Door has a guide-track cleaning device for clearing materials such as Styrofoam and wood chips. The C&M Crusher Door is shown with solid steel bars to break wood and other rigid materials.

The C&M PreCrushCompactor is manufactured with C&M baling press QUALITY and not the lower “industry accepted” compactor quality.

Crusher Door

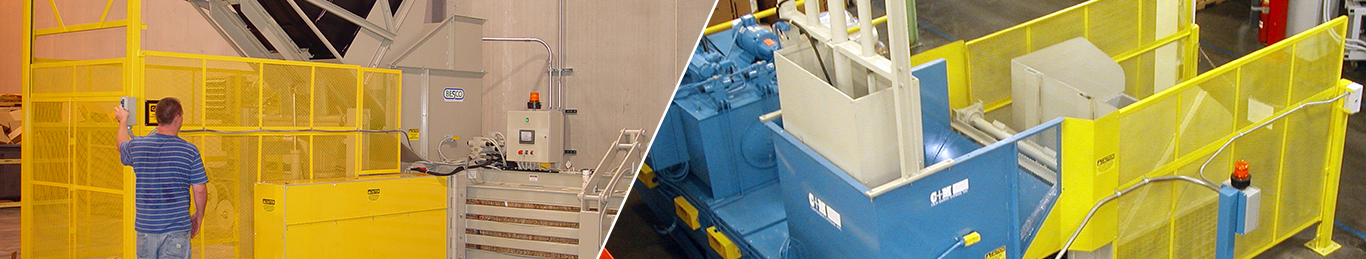

C&M manufactures the CM PreCrushCompactor, but if your application is less demanding, C&M distributes quality low cost general waste compactors.

2.71 to 4.22 cubic yard Stationary Compactors

1.58 to 2.31 cubic yard Stationary Compactors

Compactors 1.51 cubic yard Self‐Contained Compactors