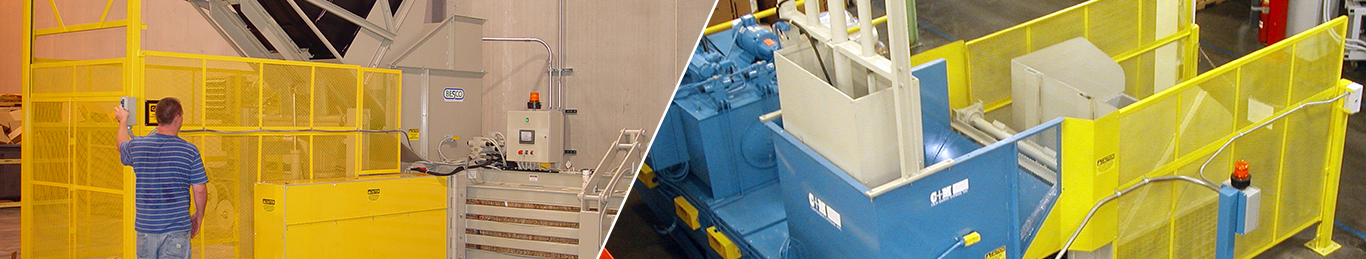

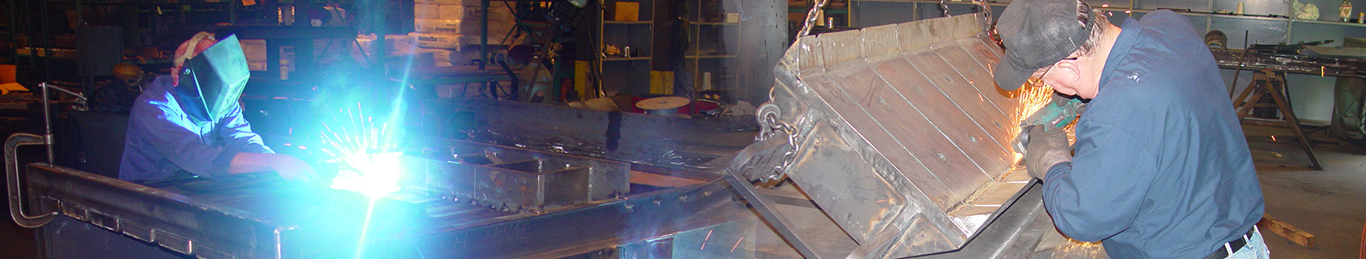

C&M Baling Systems manufactures many different styles of vertical down packing baling presses, from the industry standard 60” wide vertical down packing baler to custom designed verticals. C&M offers many features for our vertical down packing baler line, from low profile vertical balers which can fit into virtually any room, to features on the balers such as, auto-lock eject, rear feed chutes fed by conveyor or cart lifter/dumpers, fixed or spring loaded material retainer “dogs”, wire return chutes, tie-through doors, hydraulic eject, auto cycling, etc. C&M’s verticals are manufactured to order and are very heavy-duty. Examples of C&M’s vertical down packing balers:

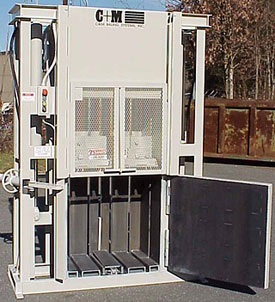

C&M Low profile down‐stroke vertical baler

The C&M Low profile down‐stroke vertical baler is design to operate under low ceiling heights. The C&M 2030 LPV has an 18″ x 30″ front infeed opening with a vertical sliding safety gate and electrical interlock. An optional 18″ x 30″ rear infeed chute system is available.

The C&M Low profile down‐stroke vertical baler is design to operate under low ceiling heights. The C&M 2030 LPV has an 18″ x 30″ front infeed opening with a vertical sliding safety gate and electrical interlock. An optional 18″ x 30″ rear infeed chute system is available.

95″ high 66″ wide 48″ long with 32″ x 61″ footprint

- Easy‐to‐Handle Bales

20″ L x 30″ W & 20‐32″ H

150‐175 lbs bale weight

- Hydraulic Power Unit

Top recessed above platen

5 HP 220‐volts single & 240/460 3HZ

Bale density control

- Twin Compression Cylinders

30,000 LBS Force

Up to 50‐PSI platen force

Unique C+M “J” bars for proper cylinder stroke

C&M 3630VHDD & 4020VHDD Vertical Down‐Stroke Balers

The CM3630VHDD and CM4020VHDD are also in C&M’s small line of extra heavy duty vertical down stroke balers and are constructed with a high‐density baling chamber for 36″ wide x 30″ long x 30‐40″ high bales (in‐chamber) or 40″ wide x 20″ long x 24‐30″ high bales (inchamber).

The CM3630VHDD and CM4020VHDD are also in C&M’s small line of extra heavy duty vertical down stroke balers and are constructed with a high‐density baling chamber for 36″ wide x 30″ long x 30‐40″ high bales (in‐chamber) or 40″ wide x 20″ long x 24‐30″ high bales (inchamber).

These balers are great for small OCC (cardboard), paper trim, office paper, plastic film, textile waste, cloth, industrial packaging waste, metal foil, and many other miscellaneous small materials.

CM60HDD with 6" or 7" Cylinder

CM72HDD with 7" Cylinder

CM48HDD with 6" or 7" Cylinder

C&M’s EXTRA HEAVY-DUTY STRUCTURAL STEEL DESIGN VERTICAL DOWN PACKING BALERS — NOT THE INDUSTRY STANDARD

CM 48HDD, 60HDD AND 72HDD with C&M Auto-Bale Eject

- C60HDD with 6″ or 7″ Cylinder

- CM72HDD with 7″ Cylinder

- CM48HDD with 6″ or 7″ Cylinder

- Extra Heavy-Duty Structural Steel Construction

- Strong High Density Baling Chamber for the tough jobs

- Bale size is 48”, 60” or 72” wide x 30” deep x 24-48” high

- Hydraulic Power Unit with 10-HP 230/460 volt motor

- PLC or “Smart Relay” control and Push Button Panel

- Exclusive C&M Auto-Bale Eject to engage bale eject hooks

- 20-gallon Hydraulic Reservoir filled w/ ISO Grade 46 fluid

- Door & Feed Gate Interlocks with Safety Gate “watch-dog”

- Replaceable UHMW Platen Wear Strips

- Adjustable down-stroke time delay for denser bales

- 70,650-lbs compression force with 6-inch bore cylinder

- 96,163-lbs compression force with 7-inch bore cylinder

Some Available Options

- Spring Loaded or Gravity Material Hold Downs – optional

- Wire Return Chutes

- Hydraulic Oil Reservoir Heater

- Lifting Lugs for Crane Lifting

- Solid Sheeted Safety Gate

- 380/400/415 or Volt Motors or 220 Volt Single-Phase Motor

- 15-HP Motor for Faster Ram Cycles

- “Two-Hand” Push Button Bale Eject Control

- Wire-Slot Finger Guards (rear only)

- Bale Lifter-Arm Cover

- Add second Auto Eject Lift Assembly

- NEMA 4 Electrical Enclosures and Weatherizing Features

- Bolt on Weather Cover for Hydraulic Power Unit

- Safety Relay & Trojan Safety Switches

- Slotted Bale Door for Closed-Door Bale Tying

- Bale Door Safety Switch Recessed into Door Frame

C&M STANDARD DUTY VERTICAL COMMERCIAL & WAREHOUSE BALERS

C&M commercial and warehouse vertical down stroke balers are offered in numerous sizes for various applications. From the smallest 30” wide by 16” deep baling chamber size or the largest 72” wide by 40” deep baling chamber, these balers bale most materials and are designed to produce many bale sizes. The standard “mill size bale” is 60” wide, 30” long, and 48”-54” high and compressed/baled within a baling chamber 60” wide x 30” deep…definably the most commonly used vertical down stroke baler.

When a baler is to be located outdoors, NEMA-4 electrics, special paint, and hydraulic fluid heaters are needed.

Download our brochure for some additional models offered by C&M Baling Systems .

Solid Sheeted Safety Gate

Slotted Tie‐Through Door

Double‐Door for Front Loading and Rear Eject

Wire Return Chutes

Spring Loaded Material Hold Downs