C&M offers the world’s largest selection of Horizontal Single Ram Full-Eject Manual Tie balers. This series of unique baling presses are referred to as “manual tie full-eject” because once the bale tie wires are manually inserted and locked by the baler operator, the completed bale is pushed fully out of the baling chamber by hydraulically opening the end door and extending the compression ram. These balers are excellent for baling multigrades of materials because of the 100% separation of each bale. Cotton and textile fibers, thin slick films, shredded carpet materials, foam rubber, fiberglass, and other difficult-to-bale materials can be proficiently baled with a C&M Full-Eject Baler. Some C&M full-eject models include extra long 10″ or 12″ long bale density retention arms (dogs) that are useful retaining compressed materials so they do not recoil back into the baler infeed hopper. When loading the low-profile style of C&M full-eject baler at high rates, the operator can lock wire ties and eject a completed bale onto a conveyor and start compressing a new bale in less than 2 minutes. These multi-material full-eject balers cost about 50-percent more than standard closed-end horizontal balers but, when needed, provides the most effective method of baling certain materials and when baling various grades of recyclables with one baling press.

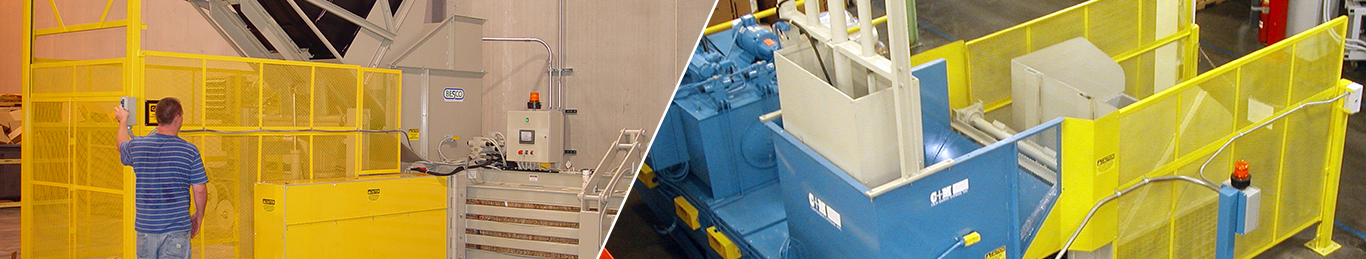

C&M Full-Eject Horizontal Manual Tie Baling Presses are usually loaded by and have the efficiency determined by the discharge rate of pneumatic or belt conveyors but can be loaded by a cart dumper or manually. Throughput is also dependant on the number of ram cycles required to form each bale and the speed of the compression ram. Most C&M full-eject balers have 30 or 40 HP power units, but can be custom designed for your application.

C&M Full-Eject Horizontal Manual Tie Baling Presses are usually loaded by and have the efficiency determined by the discharge rate of pneumatic or belt conveyors but can be loaded by a cart dumper or manually. Throughput is also dependant on the number of ram cycles required to form each bale and the speed of the compression ram. Most C&M full-eject balers have 30 or 40 HP power units, but can be custom designed for your application.

When a large infeed opening or a large bale size is needed (such as for sheets of foam rubber), the baler design requires wire ties to be inserted from the sides of the baler. For infeed of smaller materials (such as for textile fibers or shredded carpet), a different lowprofile baler design requires the wire ties to be inserted from the top of the baling chamber.

When a large infeed opening or a large bale size is needed (such as for sheets of foam rubber), the baler design requires wire ties to be inserted from the sides of the baler. For infeed of smaller materials (such as for textile fibers or shredded carpet), a different lowprofile baler design requires the wire ties to be inserted from the top of the baling chamber.

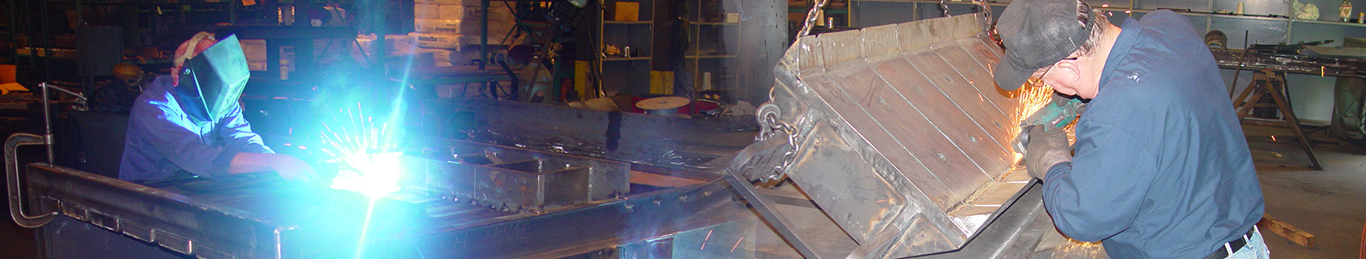

Most C&M Full-Eject balers use 7″ or 8″ bore compression cylinders, but some custom applications can utilize 10″ bore compression cylinders and 50 HP power units. Due the length of the compression ram, these balers are longer than standard closed-end horizontal balers. C&M does not offer the shorter and lower cost twin cross-type cylinder baler designs due to well known servicing issues.

To help confirm your model selection a C&M factory or C&M dealer representative can furnish you with a specification sheet and layout drawing for any C&M Full-Eject baler model or make a recommendation for you. Many C&M full-eject balers have been “custom-designed” for creative applications.