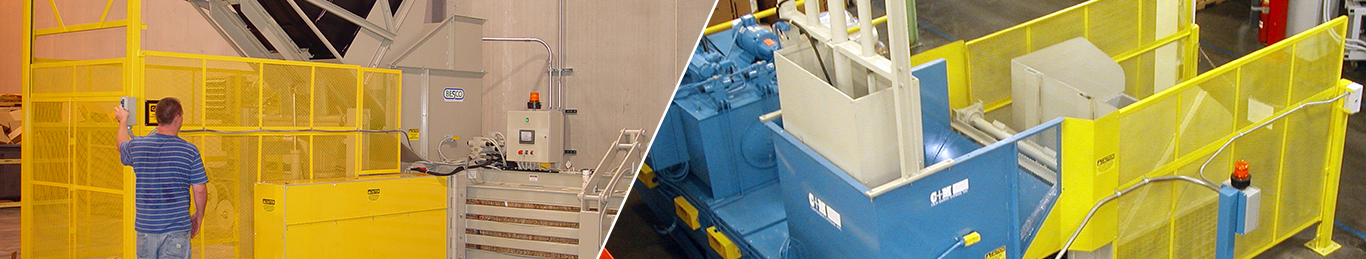

There are three styles of horizontal single ram manual tie balers. This series of balers are referred to as “manual tie” because the bale tie wires or straps are inserted and locked by the baler operator while the bale is held inside the baling chamber. For lowest cost models, select a C&M closed-end series where the ram compresses materials against the baler end door. For more difficult to bale materials that retain excessive memory after compression or do not retain memory, select a manual tie open-end model that utilizes an extrusion chamber to provide the resistance for bale compression. And, for the most difficult to bale materials, or when regularly baling several different types of materials, see our section on Multi-Material Full Eject balers.

C&M Horizontal Manual Tie Baling Presses are easy to load and require much less manual labor (man-hours) than vertical balers. Horizontal manual tie balers are commonly used to bale volumes of 1000 to 5000 pounds per hour, but the actual volume can be more or less depending on the types of material to be baled. Throughput is dependant on the type of material(s) to be baled, the size of the selected baler infeed hopper, and the degree of automation used to load materials into the baler.

C&M Horizontal Manual Tie Baling Presses are easy to load and require much less manual labor (man-hours) than vertical balers. Horizontal manual tie balers are commonly used to bale volumes of 1000 to 5000 pounds per hour, but the actual volume can be more or less depending on the types of material to be baled. Throughput is dependant on the type of material(s) to be baled, the size of the selected baler infeed hopper, and the degree of automation used to load materials into the baler.

In addition to labor required, if any, for loading materials into the baler, closed-end manual tie balers require 4 to 5 minutes of operator activities per bale and open-end manual tie balers require about 3 minutes per bale. In comparison, labor to load and operate vertical balers is 30 minutes to 5 hours per bale. If no baler operator is to be regularly available, or if the volume of materials to be baled exceeds about 3 tons per hour (less for some types of materials), a horizontal automatic tie baler should be selected – see our section on C&M Horizontal Automatic Tie balers

When deciding the required size for the baler compression cylinder (6″, 7″ 8″ bore, etc.) and ram cycle time (cycles-per-minute), these two selections are mostly dependant on the type of materials to be baled and the efficiency of loading materials into the baler. There is no advantage to having a compression ram that cycles faster than needed to accommodate the rate of loading materials.

The most common mistake in selecting a horizontal baler is choosing one with a smaller than needed infeed hopper opening. The second most common mistake is choosing one that does not have enough compression force to form dense bales. Also, careful consideration should be given to the estimated weight and size of finished bales to be certain a shipping trailer or sea container can be loaded to at least 40,000-lbs.

The most common mistake in selecting a horizontal baler is choosing one with a smaller than needed infeed hopper opening. The second most common mistake is choosing one that does not have enough compression force to form dense bales. Also, careful consideration should be given to the estimated weight and size of finished bales to be certain a shipping trailer or sea container can be loaded to at least 40,000-lbs.

To help confirm your model selection, a C&M factory or C&M dealer representative can furnish you with a specification sheet and layout drawing for any C&M baler model or make a recommendation for you. Remember, (1) select a hopper opening large enough for your materials to fall freely into the baler, (2) a compression ram (cylinder bore) powerful enough to form dense bales of your material(s), and (3) a hydraulic power unit that provides just enough speed to handle the volume of materials you need to bale.