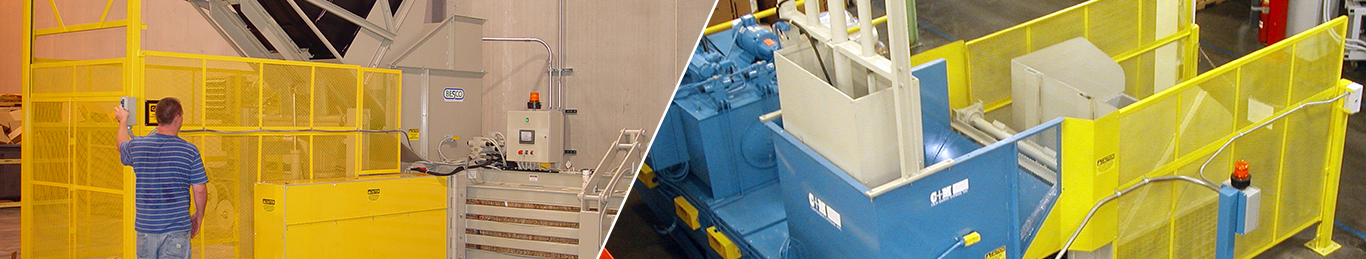

This high capacity and labor-free series of C&M balers have open-end extrusion baling chambers and are referred to as “automatic tie” or “auto tie” balers because bale tie wires are pulled from spools, inserted, cut, and twisted by the C&M automatic wire tie system. This dependable auto-tie system is attached to the heavy-duty baler frame, has a special designed ram platen (ram face), and utilizes an independent easily adjustable hydraulic system that is mounted onto the baler hydraulic power unit. The two hydraulic systems are intergraded electrically and have common PLC (programmable logic controller) controls. An endless stream of bales can be extruded from the baling chamber with completed bales only requiring removal from the area when there is no space remaining at the end of the baler. Most, but not all, types of materials can be baled automatically at high rates – without operator intervention. For applications where high volumes are not needed, C&M auto-tie balers can be in located a “back room” and will start operating only when materials load into the baling press infeed hopper.

Waste or recyclable materials are usually loaded into automatic tie baling system by an attached cart dumper, a belt conveyor, or an air evacuation system, but occasionally by hand or forklift dumper. It is important that an automatic baler has a sufficiently size infeed opening with an efficient materials delivery system. When waste materials are consistently delivered to the baler, throughput and efficiency is dependant on (1) the loose infeed density of the materials to be baled, (2) the size of the selected baler infeed hopper, and (3) the capacity of the hydraulic power unit, which determines the maximum cycles-per-minute of the compression ram. The C&M automatic wire tie system applies wires to a compressed bale in 25-28 seconds. Additional material can continue to load into the baler hopper during this bale tying process.

Waste or recyclable materials are usually loaded into automatic tie baling system by an attached cart dumper, a belt conveyor, or an air evacuation system, but occasionally by hand or forklift dumper. It is important that an automatic baler has a sufficiently size infeed opening with an efficient materials delivery system. When waste materials are consistently delivered to the baler, throughput and efficiency is dependant on (1) the loose infeed density of the materials to be baled, (2) the size of the selected baler infeed hopper, and (3) the capacity of the hydraulic power unit, which determines the maximum cycles-per-minute of the compression ram. The C&M automatic wire tie system applies wires to a compressed bale in 25-28 seconds. Additional material can continue to load into the baler hopper during this bale tying process.

When deciding the required size for the baler compression cylinder (7″, 8″, 10″ bore, etc.) and ram cycle time (cycles-per-minute), these two selections are mostly dependant on the force required to bale the type of materials and the efficiency of loading the materials into the baler. There is no advantage to having a compression ram that cycles faster than needed to accommodate the maximum rate of loading materials. However, the baling press hydraulic system must be sufficiently sized and powered to process any surges of material loading. Be certain a shipping trailer or sea container can be loaded to at least 40,000-lbs, so careful consideration should be given to the estimated weight and size of finished bales.

To help confirm your model selection a C&M factory or C&M dealer representative can furnish you with a specification sheet and layout drawing for any C&M baler model or make a recommendation for you. Baler loading calculations can be complex when utilizing a pneumatic loading system for high-volumes of low-density materials. If needed, don’t hesitate to request assistance from C&M. Remember, (1) select a hopper opening large enough for your materials to fall freely into the baler, (2) a compression ram (cylinder bore) powerful enough to form dense bales of your material(s), and (3) a hydraulic power unit that provides some extra speed and power to handle any surges of materials so the auto-tie baler will not be a bottleneck in your production system.

To help confirm your model selection a C&M factory or C&M dealer representative can furnish you with a specification sheet and layout drawing for any C&M baler model or make a recommendation for you. Baler loading calculations can be complex when utilizing a pneumatic loading system for high-volumes of low-density materials. If needed, don’t hesitate to request assistance from C&M. Remember, (1) select a hopper opening large enough for your materials to fall freely into the baler, (2) a compression ram (cylinder bore) powerful enough to form dense bales of your material(s), and (3) a hydraulic power unit that provides some extra speed and power to handle any surges of materials so the auto-tie baler will not be a bottleneck in your production system.