BALER INFEED CONVEYORS & BALE REMOVAL CONVEYORS

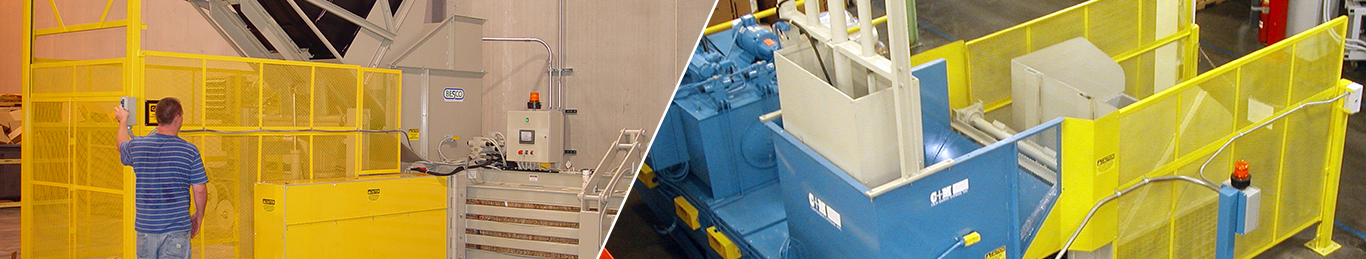

Conveyors increase the efficiency of material handling. C&M Baling Systems offers many different options on a range of conveyors including hinged steel belt conveyors, sliderbed belt conveyors, powered roller conveyors, gravity roller conveyors and specialty conveyors. The conveyor(s) are designed for the sizes, types, and volume of material being conveyed into the C&M baler. The conveyors are incorporated into the C&M operator control system and integrated into the hydraulic system. C&M will engineer the baler/conveyor system to keep up with your required production.

Hinged steel belt pit conveyor with cleats, feeding tissue broke; tissue donuts, tissue logs, slab waste and trims into a C&M Open‐End, Double Tension Automatic Tie Baling Press. The pit section of this conveyor is 10′ long and sloped below floor level to make loading by dump cart, forklift or by hand. This design also helps make daily housekeeping simple to perform.

"Rough‐Top" PVC inclined sliderbed belt conveyor feeding OCC(cardboard) into a C&M Closed‐End Manual Tie Baling Press. This conveyor is designed for loading 36" off the floor for more ergonomic hand loading.

Sliderbed belt conveyor loaded with shredded paper from shredding trucks into a C&M Open‐End Automatic Tie Baling Press. The conveyor has very high side rails to contain the shredded paper and avoid spillage. The belt has 3" rubber cleats to assist in moving the materials up the belt and into the baling

Cleated, straight infeed sliderbed belt conveyor feeding whole and flattened OCC (cardboard) into a C&M Open‐End Automatic Tie Baling Press. This conveyor was designed with floor‐grade infeed hopper for hand and cart feeding.

Sliderbed belt conveyor with cleats feeding used clothing into a C&M Open‐End, Automatic Tie Baling Press, and is first unloaded by a C&M custom cart/lifter dumping system. The used clothes then inspected and metered onto the conveyor via a C&M material sorting table.

Sliderbed belt conveyor being loaded with shredded broke and slab waste while being fed tissue trim by an airsystem all unloading into a C&M Open‐End Automatic Tie Baling Press. The conveyor has very high side rails to contain the shredded material and avoid spillage. The belt is also cleated to assist in moving materials up the belt and into the baling press.