Why are the C&M Baling Systems baling presses so desirable?

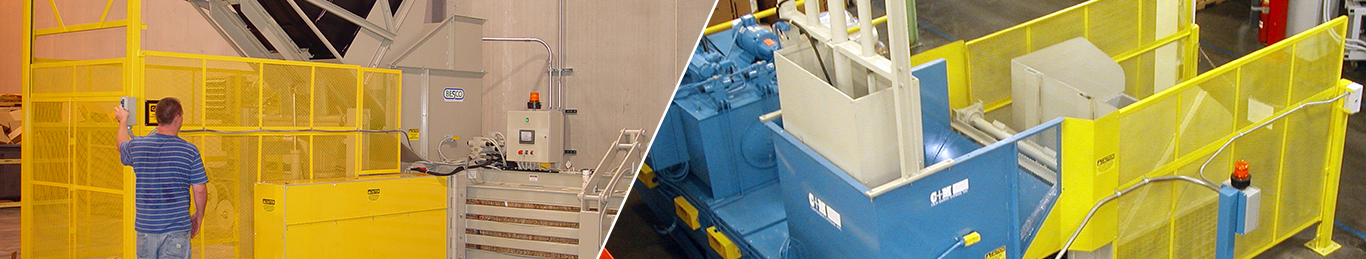

C&M baling presses are engineered with simplicity, serviceability, and safety in mind. C&M engineers design hydraulic and electric circuits for virtual trouble-free operation and low maintenance cost with standard hydraulic components. Complicated hydraulic systems with proprietary components are time-consuming to maintain and costly to repair. Our engineers make every effort to use off-the-shelf parts, not expensive difficult-to-locate hydraulic components that some call “easy-to-service custom designed regen manifolds”. Your service personnel will be pleased with a C&M designed hydraulic system…easy to service and easy to maintain.

C&M heavy-duty baling press structures and industrial grade compression cylinders will last for many years in most environments. C&M baler floor liners are made from hardened steel or of long-lasting & serviceable composite materials that can be removed and replaced when needed. A special C&M compression platen base can be added to virtually eliminate metal or lubricant contamination for textile or non-woven fibers, food products, or other baling applications.

The C&M Baling Systems product line

C&M balers are designed for baling paper, corrugated (cardboard), non-wovens, plastics, textiles, foam rubber, fiberglass, carpet, tobacco, agriculture waste, biomass, and non-ferrous metals.

- Closed-door manual tie horizontal baling presses

- Open-end automatic tie horizontal balers

- Full-eject style balers for baling multi-materials, foam rubber, carpet shavings, and difficult materials

- Vertical down-stroke balers and down packing baling presses front loading and rear loading

- PreCrushCompactors to increase waste container loads for fewer paid trips to the landfill

- Baling presses for cotton, tobacco, textile goods, manmade fibers, and other natural fibers

- Portable or mobile balers for baling biomass & agriculture waste

- Custom designed baling presses for unique applications and balers with special features

- Cart dumpers, cart lifters, and dump carts

- Material handling belt conveyors

- Shredders, fluffers, and other material conditioners

- Custom designed air conveying systems for loading balers

C&M has manufactured balers for companies such as Kimberly-Clark, Mead Paper, International Paper, Dell Computer, 3 M Company, Polo Ralph Lauren, Avery Dennison, Mitsubishi Electric, Sara Lee, Kodak, GAF, Proctor & Gamble, Duke Power, Mohawk Carpet Mills, Miller Brewing Company, Woolworth’s Distribution, Walden Books, Barnes & Noble, Freightliner Trucks, Crate & Barrel, Shopko Stores, Nautica, Ashley Furniture Industries, and other well known national or international organizations, as well as many lesser known companies.

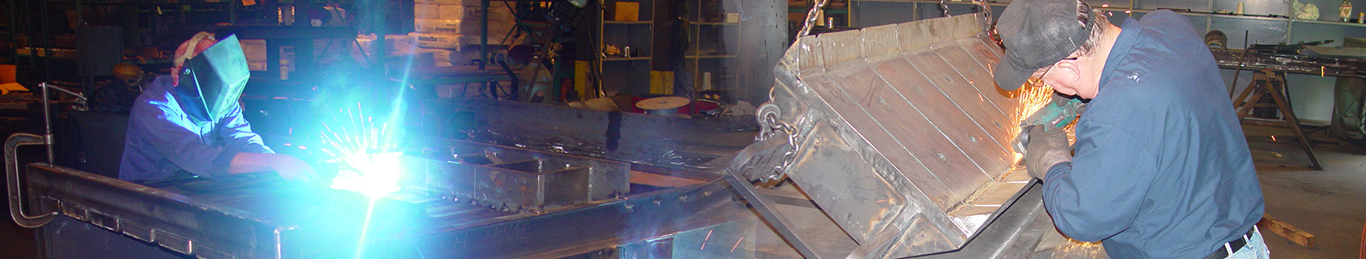

Our manufacturing process

Strong baling presses are usually made from structural steel, not formed sheet metal commonly used by other companies to reduce cost. The C&M factory saws lasers or plasma burns thick steel plate, and then welds them together to form the primary baling press structure. Then sheet steel is sheared to add the in-feed hoppers and safety guarding. Pre-assembled hydraulic systems and electrical control systems are installed and the baler is then always test-operated prior to cleaning and painting. Our factory utilizes prior baler designs to fabricate jigs and fixtures for both the standard C&M products and parts.

Our employees strive to deliver completed products with these heavy structures and strong welds to provide years of useful baling press life. C&M balers are often installed outdoors so NEMA-4 electrics are often incorporated and our finished product is cleaned, primed, and then covered with a two-part hardened paint.