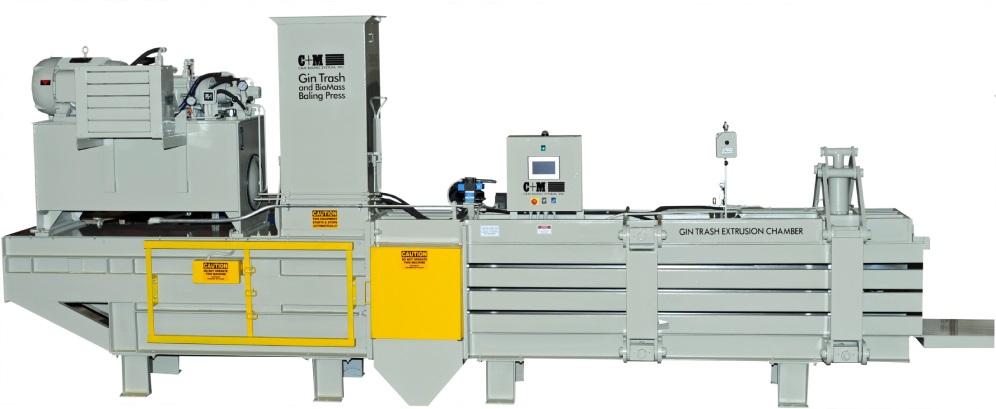

C&M2424EC Series Cotton Gin Trash & Biomass Baling Press

C&M2424EC Series Cotton Gin Trash & Biomass Baling Press (patent pending) is the result of over 15 years of testing and trials to bale organic waste resulting from cotton ginning and cotton mote processing operations. This press has a 40HP hydraulic power unit, fully wired electrical box with an independent PLC controlled operators panel complete with a simple touchscreen. The versatility of this new baling extrusion style press allows not only cotton gin waste, but bagasse, and Miscanthus, and other energy crops to be baled efficiently. Bale density is 29-34 lbs./sq./in…denser than UD bales of cotton!

Cotton gin waste is baled as produced by the ginning process and at the same rate as discharged from the gin. The baling properties of gin trash (organic waste or biomass) vary significantly over short periods of time. The incorporated features of the baling press design and controls program reset the extrusion chamber and compression force as required to maintain well-formed dense bales of the waste material…and as a result, a new byproduct with commercial value is being created. Most likely, less labor is required to operate the semi-automatic extrusion press than is utilized to handle, load or disposed of gin waste stored outdoors.

C&M believes the primary reason profitable markets for gin waste have not developed over the past 40 years (since the creation of the EPA) is that gin trash (and other types of agricultural biomass) have never been packaged (baled) efficiently or correctly – to be handled multiply times, loaded and shipped long distance, and stored for many months as a feed stock for energy, livestock, or to convert to other products. For a markets and usage to expand, there must be the commercially packaged raw material, consistent quality, and a large dependable supply available 12 months each year. Installing a C&M gin trash and biomass baling press does not require that all cotton gin waste must be baled, but producing bales of gin trash allows you to develop your future markets for the last remaining byproduct of the cotton ginning process. CONVERT YOUR GIN’S WASTE/BIOMASS INTO A PROFITABLE BYPRODUCT.