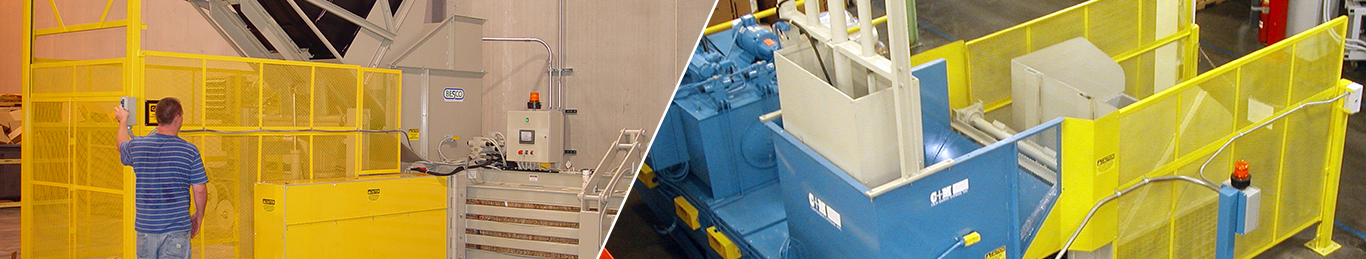

C&M balers are designed for baling paper, corrugated (cardboard), non-wovens, plastics, textiles, foam rubber, fiberglass, carpet, tobacco, agriculture waste, used clothing, biomass, non-ferrous metals, cotton or man-made fibers, and other materials.

Please read over the following information to help you decide what style of baler best fits your application.

Styles or Types of Balers

There are several “styles” of balers and baling presses. Horizontal balers in general are the most efficient and horizontal automatic tie horizontal balers are for higher production rates. Vertical down-stroke balers are for lower volumes or special materials. Most horizontal balers retain completed bales inside the baling chamber until other completed bales pushes them out of the chamber. The determination as to what style of baler best fits your application is primarily determined by (1) the volume of material, (2) the size of the material, (3) and sometimes the type of material. Availability of labor to load and operate the baling press is an important consideration.

C&M Standard Design Horizontal Baler Model Descriptions

There are four “Styles” of standard C&M horizontal balers. Closed-End manual tie, Open-End manual tie, Open-End automatic tie, and Full-Eject manual tie.

Baler throughput (output capacity) is determined by the “cubic feet of displacement” (within the baling chamber) while the baler ram cycles into the baling chamber.

Throughput or Capacity is determined by: Style of baler, length & width of infeed opening, height of bale, length of bale, speed of compression cylinder (cycles/minute), and the characteristics of the material(s) to be baled or loose infeed density vs. compressed or “baled” final density.

Common bale heights are available: 24″, 30″, 40″, or 42″.

Many hopper infeed openings are available as indicated by our model numbers series:

| BALER MODEL | Opening Length | Opening width |

|---|---|---|

| CM2424 Series | 24 inches | 24 inches |

| CM3030 Series | 30 inches | 30 inches |

| CM3430 Series | 34 inches | 30 inches |

| CM3442 | 34 inches | 42 inches |

| CM5030 Series | 50 inches | 30 inches |

| CM5042 Series | 50 inches | 42 inches |

| CM5046 Series | 50 inches | 46 inches |

| CM6042 Series | 60 inches | 42 inches |

| CM6046 Series | 60 inches | 46 inches |

| CM7842 Series | 78 inches | 42 inches |

| CM7846 Series | 78 inches | 46 inches |

| CM3060 Series | 30 inches | 60 inches |

C&M FULL SIZE Hopper Designs:

- 48” High over baler body with door & window

- 3 ½ sided hopper with or without flared sides 48″ high

- Any custom designed hopper

- Special quotation for additional hopper sections

Compression Cylinders (bore)

- 6” ID

- 7” ID

- 8” ID

- 9” ID

- 10” ID

- 12” ID

Note: All cylinder bores not available with some baler models

Power units & electrical

Power Unit electric motors and hydraulic pump selections determine the “speed” of the baler compression cylinder. C&M hydraulic power units are designed with a single 10 HP to 75 HP single primary motor or twin motor power units with two 20 HP up to two 75 HP motors. C&M auto-tie models have separate 15-HP hydraulic system.

When a baler is to be located outdoors, NEMA-4 electrics, special paint, and hydraulic fluid heaters are needed.

C&M STANDARD DUTY VERTICAL COMMERCIAL & WAREHOUSE BALERS

C&M commercial and warehouse vertical down stroke balers are offered in numerous sizes for various applications. From the smallest 30” wide by 16” deep baling chamber size or the largest 72” wide by 40” deep baling chamber, these balers bale most materials and are designed to produce many bale sizes. The standard “mill size bale” is 60” wide, 30” long, and 48”-54” high and compressed/baled within a baling chamber 60” wide x 30” deep…definably the most commonly used vertical down stroke baler.

C&M Full Eject Horizontal Balers

Full eject manual tie horizontal balers are offered with a variety of baler feed opening lengths and widths. Balers that can fully eject a completed bale are generally used for baling multi-materials, cotton or textile fibers, & foam rubber, but cost more than other manual tie horizontal balers.

C&M Extra Heavy Duty Vertical Balers

C&M does not make standard duty light weight balers from formed sheets of metal, but from structural steel to withstand years of heavy-duty service. The C&M structural steel body can withstand the forces from our recommended 7-bore compression cylinder for heavier bales, which delivers 36% more compression force than a 6-inch bore cylinder. C&M 6-inch bore cylinder models are also offered, but with the same C&M extra heavy structure. These balers are available for bale widths of 30, 42″, 48″, 60″ and 72″. In chamber bales are 20″, 30″, or 42″ deep to produce bales 24″ to 48″ high.